Password

Password

Top searches

October 2017

Many small and medium-sized businesses err in thinking an ISO 9001 Quality Management System (QMS) is a static entity. It isn't. A QMS needs to evolve in order to reflect your company's evolution; it must be allowed to develop as market conditions change and your products and technologies improve. By treating your QMS as a living entity, the more likely your company will realize quantifiable benefits and maintain ISO 9001 certification.

A key requirement of ISO 9001:2015 is "continual improvement" – this refers not only to a company's products and services, but also to the QMS. To quote directly from the published ISO standard: "The organization shall continually improve the suitability, adequacy and effectiveness of the Quality Management System. The organization shall consider the results of analysis and evaluation, and the outputs from management review, to determine if there are needs or opportunities that shall be addressed as part of continual improvement."

Continual vs. continuous improvement

When referring to ISO 9001 you'll often see the terms continual improvement and continuous improvement.

Continual improvement describes individual "cycles" within the QMS, some of which may show temporary lulls or setbacks, or shed light on areas that require attention and refinement.

Continuous improvement refers to the bigger picture and the overall constant, positive trend.

But as the American Society for Quality reminds us, the two terms can be used interchangeably with little difference in meaning.

As stated, continual improvement is incorporated in ISO 9001:2015. All companies needs to do is completely follow their ISO 9001 QMS, and continual improvement will be a natural consequence.

The following processes of the Quality Management System will help your company continuously improve:

Goals and metrics

Setting goals on various levels and using metrics to measure performance.

Customer feedback

Measuring what customers think about the company and its products or services.

Internal audits

Periodical evaluating if the company still meets all ISO 9001 requirements.

Corrective action

Systematic identification of underlying causes of existing problems and then correcting these causes.

Preventive action

Systematic search for potential problems and correcting their underlying causes before the problems can occur.

Management review

Management's periodical review of key business indicators and planning of improvement initiatives.

TIP:

We recommend keeping all employees involved in the ISO 9001 Quality Management System. A great idea is to periodically send tips to all employees.

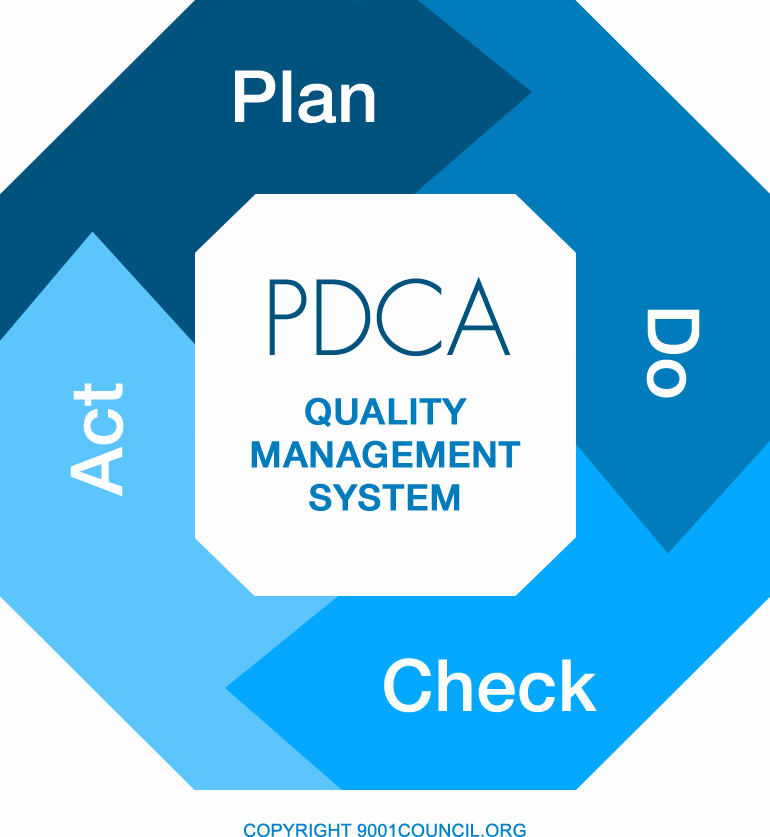

According to the American Society for Quality, one of the most widely used tools for ISO 9001 continuous improvement is a four-step quality model – the plan-do-check-act (PDCA) cycle, also known as the Deming or Shewhart Cycle. We generally agree with this opinion and believe the PDCA model is a valuable tool for ensuring a robust QMS, generating continuous improvement and maintaining ISO 9001 certification.

The four steps in the PDCA cycle are explained below. Following them will lead to continuous improvement.

Revising the ISO 9001 procedures and other documents should be a normal part of the ever-improving Quality Management System.

These revisions can range from small corrections to a total makeover of the entire ISO 9001 documentation. If you find your company's QMS to be bureaucratic and cumbersome, if you find your employees feeling negative about ISO 9001, or if you need to spend excessive time preparing for each audit, then your Quality Management System has plenty of opportunities for improvement and you should consider a complete makeover.

Far too many Quality Management Systems fail. The reasons are almost always the same and can easily be avoided.

A fairly common indicator that a company's QMS is heading towards failure is a majority of employees complaining about ISO 9001. Most complaints are about excessive bureaucracy and paperwork, and extra work before audits. At the same time, those employees feel there are no benefits to ISO 9001. These problems are not the fault of the Standard, but result from the way the Quality Management System has been set up.

Typical problem #1: management attitude and purpose

If management implements ISO 9001 solely for marketing reasons or due to external pressure, the resulting QMS will often lack the all-important internal improvement component.

It is possible to pretend (and fool even an experienced auditor) to have an effective Quality Management System in place, but its cost due to bureaucracy and efficiency could be huge.

Typical problem #2: ISO 9001 implementation by consultants

Frequently management decides to hire consultants to implement ISO 9001.

The consultant writes the ISO 9001 procedures and other documents, and in many cases also provides training.

Typical problems are:

The consultant is unfamiliar with the company and the nature of its business and culture. Unwilling or unable to adjust to the company's unique requirements, he may set up a "one-size-fits-all" ISO 9001 system The resulting Quality Management System is not geared to the specific needs of the company and (particularly for small and medium-size companies) is excessively bureaucratic and labor intensive.

The consultant tries to justify high fees by setting up an overly complicated and convoluted QMS.

The consultant is inflexible. Instead of creatively molding the ISO 9001 Quality Management System to fit the realities of the company, the consultant tries to mold the company to fit his own "one-size-fits-all" approach.

More information

We encourage you to read our article about the pros and cons of ISO 9001 consultants.

The USA section explains the differences between hands-on and hands-off consultants, and shows the impact these differing styles of consultancy can have on your company's ISO 9001 implementation.

Typical problem #3: ISO 9001 Management Representative without power

Executive management of some companies erroneously consider the ISO 9001 Quality Management System to be a documentation task rather than the implementation of an improved and systematic management style.

A consequence of this misconception is the appointment of an ISO 9001 Management Representative without the power to make real changes.

In such situations, it is very common to find an increasingly disenchanted Management Representative who is desperately trying to improve the company while top management pays mere lip service to their QMS.

Typical problem #4: insufficient resources

Unless a company's overall performance is well above average, setting up an ISO 9001 system usually requires significant resources: the Management Representative needs to be trained, top management needs to learn about the Standard and its benefits, procedures and documentation need to be written, work processes throughout the company must be analyzed and streamlined, and employees have to be trained, etc.

It is crucial to the success of the ISO 9001 implementation that management allocates enough time, as well as financial resources (for example, for employee training, templates for the ISO 9001 documentation, or for internal audits and auditor training, etc).

Typical problem #5: lack of improvement

It is a common misconception that a Quality Management System needs to be implemented, certified and that's it.

In reality, the QMS must constantly evolve as the company changes, as market conditions change, as products change, as technologies improve and as the competition moves forward.

Typical problem #6: making it too complicated

ISO 9001 does not need to be complicated: the easier the documentation is to follow and understand, the better the resulting QMS.

There are countless possible causes for overly complicated and bureaucratic Quality Management Systems.

This includes the problems mentioned above, along with inflexible auditors, bad examples, bad documentation templates and bad training.

TIP:

The problems highlighted above are a direct consequence of management action and attitude, rather than the often-blamed employee resistance to ISO 9001 implementation. Ensuring top management buys into the benefits of ISO 9001 and remains actively involved in the implementation process, will dramatically improve any Quality Management System. An executive overview by a competent trainer or online course prior to the start of the implementation is therefore highly recommended.

TIP:

Implementing ISO 9001 internally as opposed to hiring a consultant is cheaper and will result in a more efficient QMS. We recommend appointing a Management Representative who is a manager within the company, with sufficient authority to make the required changes. The representative must then be trained in all aspects of the 9001 Standard (there are lots of excellent public and online courses available) and given the resources needed to purchase a set of documentation templates. Finally, it is important to ensure all functions in the company allocate enough time to work with the representative.

TIP:

Choose your ISO 9001 registrar carefully: pay particular attention to auditor background (for example, some may consider former military auditors to be rigid and inflexible in their interpretation of the 9001 Standard) and to their attitude towards sharing ideas (in order to ensure objectivity, auditors are not allowed to consult; however, some registrars permit their auditors to share their experiences).

TOP